With the new needle things went MUCH better! The fabric still puckered a bit on curves, but that came out with the iron. And I was looking to at least eliminate the snags and runs.

So on with sewing together all the lining pieces! I didn't use the silk thread, so I'll be able to return that. I wasn't wild about it anyway, because in the speciality threads there's not as much color selection. There was only one light purple choice and it was waaaaay gray looking and not a match. At all.

|

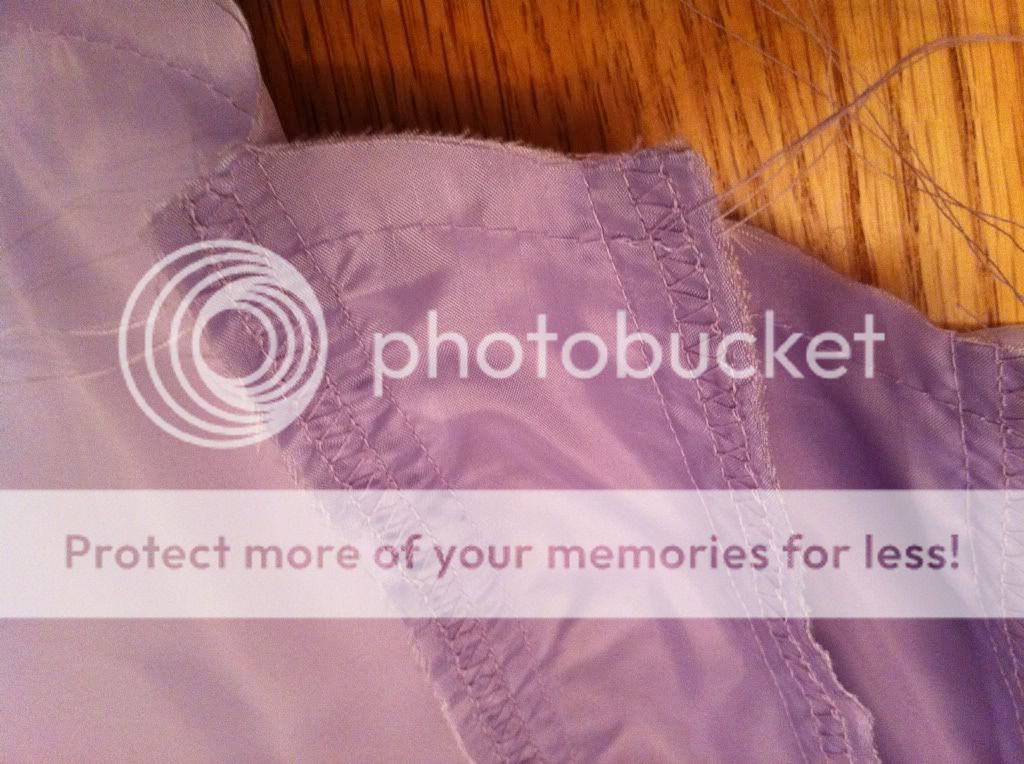

| Outer layer and lining layer all sewn together Seams aren't pressed yet |

Now to combat the next problem, which I knew was coming from past experience with specialty fabrics, but out of lack of time, I've never done anything about it before. Fraying.

|

| Some fraying is already beginning to occur and will only get worse as I iron down the seam allowances and this layer is worked on to embroider it |

The Vogue pattern called for the seam allowances of the outer layer to be pressed and top stitched, just like I did with the lining layer. But I did that on the lining layer to create channels to run the boning through. I didn't do this on the outer layer of the mock up to save time. Remember, the mock up is all about a proper fit off the pattern pieces, not a complete garment.

Top stitching the outer layer can be about a few things. First off, it's a "look." Just part of the design so to speak. The same way you might choose pleats or add a strip of lace for embellishment for a top. And in the case of this garment, which is simulating the look of a true corset, the top stitching lends to that "look." Since I'm embroidering the top, I chose not to top stitch for look.

|

| Top stitching on jeans-as much for a "look" as for reinforcement of the seam |

But it can also be about reinforcement. Lending support to those seams by having another layer of stitching along them. Or reinforcement from fraying. If a fabric is prone to unravel easily, you hem it to protect the raw edge from wear and friction which leads to the fraying occurring. Or you can put another layer of stitching between the raw edge and the seam. Top stitching would qualify for this, but I've seen a highly fray-able fabric fray right between a seams stitches and go right on to unravel AT the seam on a pressure point. Bras tend to do this in the back band, for example. And I don't need to sew the seam allowance to the outside layer (where that extra line of stitching would show) for reinforcement purposes. I could just sew an extra line of seam in the allowance about 1/4" away from the actual seam.

This is one of the many reasons for a serger or overlock (a type of sewing machine that makes a special bound edge and cuts the fabric as it goes all at the same time).

|

| Example of some overlocked edges done by a serger |

While my machine isn't a serger, it has some of the zig-zag stitch and encasement stitch capabilities that would create a similar effect to serging as far as preventing fraying.

|

| I played with some of my machine's stitch capabilities on a scrap piece of lining fabric to see what would work best for the effect I wanted. |

|

| Zig-zag stitching the seam allowances of the taffeta layer with underlining |

|

| Here's what I did to each seam allowance to prevent fraying |

|

| Finished seams-that's a lot of loose threads to keep track of! |

Once I was done with the taffeta layer, I did some loose thread maintenance. I went through and removed (i.e. ripped out) all the vertical baste threads that were holding the underlining layer to the taffeta because the seams are now doing that. This is where having done the basting in black would have been beneficial to keep track of what I needed to pull out. Oh well. Then I tied off all my seam and zig zag ends. So now, the only loose threads left are the baste stitching along the tops and bottoms of the pieces.

To Do List

- Stitch down seam allowances on lining

- Stitch layers together

- Send off to mom